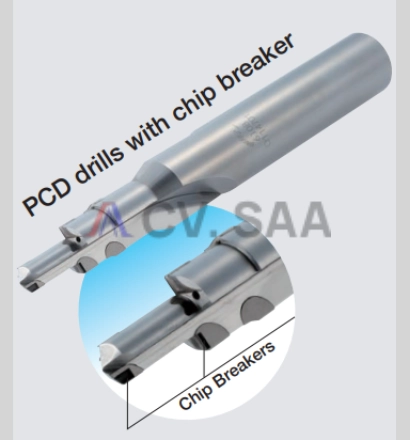

PCD drills with chip breaker

• High precision and smooth finish.

• PCD tools are superior to carbide tools in temperature resistance and prove longer lifetime in high-speed feed processing.

| Application | Enlarging and finishing a rough hole on non-ferrous steel |

|---|---|

| Machines | |

| Material | Non-ferrous metals |

| EdgeMaterial | PCD |

Product Line Up

|

| Smaller diameter PCD reamer The PCD brazed smallest diameter reamer (3mm dia.) with to improve cutting condition and tool life in processing small parts. |

| Helical PCD drill bits with oil holes Reduction on cutting resistance and improvement on swarf discharge by helical system. | |

| Fine tooth pitch PCD helical endmill High speed feeding is available by fine tooth pitch helical system. | |

|

| PCD profile reamer Reduction on production process by combining profile cutter and Reamer (Drill). |

| Multistep type PCD reamer Reducing cost by choosing appropriate electric discharge conditions on each edge step. | |

| High roundness and high-quality finish reamer High roundness with odd tooth number and high-quality finish with step edges. | |

| Fine tooth pitch PCD reamer for high precision roundness The high-quality drilling at low cost. | |

| Long PCD reamer For high-quality deep hole drilling with appropriate oil holes, guide and stepped edges. |